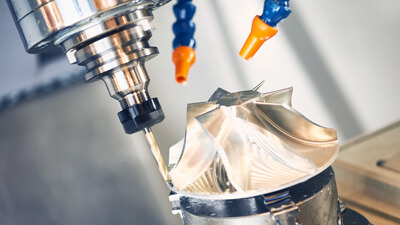

Brass is a metallic alloy that is made of copper and zinc. It has a good machinability and electrical conductivity, and is ideal for applications that require low friction. The relatively low melting point of brass (from 1,650 - 1,720 °F or 900 - 940 °C depending on composition) and its flow characteristics make it a relatively easy material to cast. It is often used in CNC machining.

Commandez en Brass

| Propriété | Valeur |

|---|---|

| Service temperature | -459.67°F (-273.15°C) and 305.33°F (151.85°C) * |

| Density | 8.73 g/cm³ |

| Tensile Strength | 267 MPa |

| Modulus of Elasticity | 82.0 - 117 GPa |

| Fatigue strength | 22.0 - 360 MPa |

* depends on alloy

Brass is a metal alloy that is made with a combination of copper and zinc. By varying the proportion of these components, the final alloy can be harder or softer. All types of brass are strong, machinable, tough, conductive, and corrosion resistant. Moreover, other metals like aluminum and lead can also be added to increase machinability (CNC machining, milling and others) and corrosion resistance. Brass has become one of the most widely used alloys thanks to its aesthetic appeal and ease of production. Most common alloys are brass C360 and 464. Brass 360 contains a relatively high amount of lead which makes it a highly machinable alloy with high tensile strength and natural corrosion resistance. It's often used to make items such as brass rods and bars. Brass 464 is also called naval brass because of its high corrosion resistance and use in seawater.

Cover image by Emilian Robert Vicol

Tous les commentaires (0)