Aluminum is a conductive metal that is lightweight and has very high corrosion resistance. Compared to other metals, aluminum exhibits lower density and appears soft. It is non-magnetic and commonly used in alloys for better mechanical properties. Aluminum alloys are often used in aerospace, shipbuilding, engineering, and many other industries.

Commandez en Aluminum

| Propriété | Valeur |

|---|---|

| Service temperature | -319°F (-195°C) and 752°F (400°C) * |

| Density | 2.70 g/cm³ ** |

| Tensile Strength | 124–290 MPa (18.0–42.1 ksi) |

| Elongation (ε) at break | 12–25% |

| Modulus of Elasticity | 68.9 GPa |

* depends on alloy, ** 6061

Aluminum is a soft but versatile material, which is utilized mostly in alloys. Due to its relatively low costs and ease of machining and forming, it is widely used in many industries and remains one of the most widespread metals. One of the key fields for aluminum is construction, closely followed by engineering.

Aluminum presents excellent conductivity of heat and electricity, comparable to copper: about one half in relation to heat and two-thirds the same electrical conductivity. This metal is recyclable without quality loss and highly durable. About 75% of ever produced aluminum is still in use.

Although relatively strong, the main features are its lightweight and corrosion resistance (after contact with oxygen it forms the layer of Al2O3). Among the most widespread aluminum alloys are 6061, 7075, and AlSi7Mg0,6.

6061 alloy is one of the most commonly used general-purpose aluminum alloys. It's a precipitation-hardened material that contains magnesium and silicon as its major alloying elements. It has good mechanical properties and exhibits great weldability. However, this alloy doesn't boast the same high strength and stress resistance as Aluminum 7075.

Zinc is the primary alloying element of 7075 (up to 6.1% zinc, 2.5% magnesium, 1.6% copper). It has a relatively high cost that limits its use. This alloy is also sometimes referred to as aerospace aluminum due to its high strength-to-density ratio and very high corrosion resistance, which makes this material ideal for marine, automotive, and aviation applications.

This alloy contains 0.6% of Mg and 7% of Si. The high percentage of silicon gives good casting characteristics. It has relatively high electrical conductivity, a moderately high melting temperature, and fairly high tensile strength. It's often used for aeronautics (wings and armaments), in the automotive industry (bumpers and engine blocks), and marine (hull and accessories). Such aluminum alloys are widely used in engineering structures and components where lightweight and corrosion resistance is required. Its composition makes it very suitable for molding, but it's more widely used for 3D printing using DMLS and SLM technology.

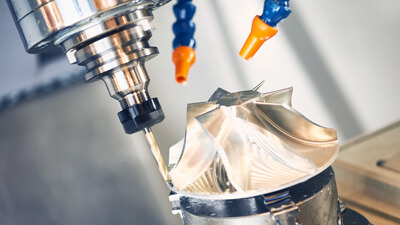

Aluminum alloys are cost-effective to machine and take less production time compared to many other metals. Aluminum machined parts are chemical resistant, electrically conductive, malleable, and possess high strength. With its natural corrosion resistance, machine aluminum allows the manufacturing of many durable and accurate parts and components. Certain post-processing measures (like anodizing, powder coating, chromate) can be applied to these alloys to influence parts’ appearance and properties.

AISi7Mg0.6 and AlSi10Mg0.6 are often used for 3D printing thanks to their weldability and excellent properties. Such 3D prints are rivaled with objects fabricated using traditional manufacturing methods.

Aluminum is 3D printed through Selective Laser Melting (SLM) or Direct Metal Laser Sintering (DMLS) technologies with a slight difference in characteristics of the end product. SLM parts pose slightly higher strength.

Aluminum is a reflective metal, which may present some challenges for laser cutting. However, it is possible to cut and engrave it with CO2 lasers.

Among the most common methods of aluminum fabricating are die casting and mold casting. Cast aluminum is versatile, corrosion resistant, retains high dimensional stability with thin walls, and can be used in almost any industry.

Aluminum alloys can be formed into specific shapes by both hot and cold methods such as rolling, extrusion, and forging. Rolled and extruded aluminum can serve as stock for fabrication through stamping, forging, and drawing to get extruded tubes, cans, and more.

Tous les commentaires (0)