PLA, short for Polylactic acid, is a common material for FDM 3D printing and one of the most used bioplastics in the world. Unlike petrochemical-based plastics, PLA is considered to be biodegradable and eco-friendly thanks to being derived from renewable materials. This plastic is extremely affordable and, thanks to its properties, is the easiest to 3D print with.

Commandez en PLA

| Propriété | Valeur |

|---|---|

| Heat Deflection Temperature (HDT) | 126 °F (52 °C) |

| Density | 1.24 g/cm³ |

| Tensile Strength | 50 MPa |

| Flexural Strength | 80 MPa |

| Impact Strength (Unnotched) IZOD (J/m) | 96.1 * |

| Shrink Rate | 0.37-0.41% (0.0037-0.0041 in/in) |

* *IZOD impact testing is a standard method of determining the impact resistance of materials

PLA is a polyester, produced from renewable resources including the sugar in maize and sugarcane. The sugar is fermented and turned into lactic acid, which is then turned into polylactic acid. For a long time, the prime fields of use for this material were in biomedical due to bioabsorbable characteristics. Within the last ten years, though, new polymerization methods came along. This made it possible to produce polylactic acid with higher molecular weight more economically. Additionally, environmental concerns also played a role in the growing popularity of PLA, which can be composed and degraded. As a result, nowadays you can find it in consumer goods, packaging, and agriculture.

In terms of mechanical properties, polylactic acid can be placed between polystyrene and PET. With a good surface finish and look, it doesn’t have a huge strength or wear resistance of more industrial-oriented plastics.

PLA has a “7” recycling identification code and can be reprocessed into the same virgin material. A good option is industrial composting. This material is more degradable compared to many other plastics. But consider that it is still plastic, so it requires either specific conditions or more time to degrade. Landfillingor household composting aren’t really effective methods of getting rid of PLA wastes. At ambient temperatures, polylactic acid degrades slowly. According to studies, products from this plastic hadn’t lost any mass over the year in seawater. And since more goods and packaging is made from PLA marked as biodegradable, it is needed to be mindful of wastage.

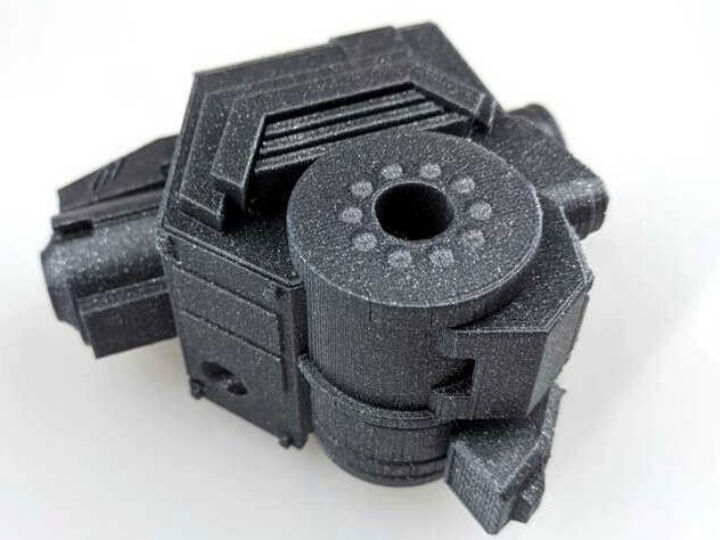

PLA is the most popular 3D printer plastic for FDM technology and can be easily sanded, painted or post-processed in a different fashion. This plastic enables working on relatively low extruder temperatures and appears to be “user-friendly”. Compared to some other filaments, there is no crucial need for a heated bed, reinforced nozzle or printer chamber to work with it. With great details transfer and attractive surface finish, it serves many generic applications of personal 3D printing.

PLA filament behaves much better than tougher plastics and usually doesn’t have a bad smell or fumes. The storage of such a material is comparatively low-key as well. On top of all that, polylactic acid is produced in a big variety of colors and used as a base material for many composites with over-the-top properties.

In FDM 3D printing polylactic acid is used a lot more than acrylonitrile butadiene styrene. While PLA doesn’t have the same strength and durability, it still suits many applications of personal printing. The shortcuts of its brittleness can be overcome through composite materials or smart approaches during the design process. Simple thickness increases and attention to layer orientation can significantly improve a part’s strength. Such smartly designed PLA parts can live a long life and even be used as components for hand tools.

ABS, on the other hand, has huge downsides when it comes to printing. From its distinctive smell to warping and delamination – it requires more involvement in the process. Additionally, printers are better have enclosures as well as a heated bed and adhesion solution to print ABS successfully. Temperature demands for it stand higher than PLA and don’t end up on just printing settings. Full control of the environment to exclude heat dropping or uneven cooling is the best practice for ABS plastic. On a positive note, well-printed parts have a slightly lower weight and increased durability. They are rigid and have a higher glass transition temperature in comparison to PLA.

PLA+ is a generic name for many PLA-based composite filaments created to showcase improved material properties. Usually, these have a better stiffness, higher melting point, lower moisture absorption. Among filament manufacturers, there are no standards regarding what exact additive is represented by “+”. Many brands don’t disclose their formulas either, so such PLA filament can be a blend of anything or just created with the use of especially fine pellets.

Other popular composites commonly include combining PLA with materials like carbon fiber and Amphora polymer. And thanks to excellent printing properties polylactic acid became a popular base material for a wide range of exotic and decorative filaments that imitate woods, metals, stones or share unique properties.

There is quite a variety of glues that work well for PLA: Cyanoacrylate (Superglue), Epoxy, Polyurethane or Silicone Glues. Additionally, some PLA parts could be bonded together with acetone.

There are grades of PLA considered to be food-safe. However, you must pay attention to the manufacturing method used for creating an object from PLA. Generic 3D printers that use PLA filaments can’t be considered a source of food-safe parts.

Filament blends may wary in their properties and have a slightly different requirements. Below is the general range for simple PLA material.

| Nozzle Temp. | 190 - 220°C |

| Print Bed Temp. | Not necessary; If used 55 - 70 °C |

| Speed | 40-60 mm/s |

| Raft | Not necessary |

| Retraction | 8 mm |

| Cooling min.time | 20 s/layer |

PLA can be molded in both amorphous and crystalline forms but it requires much attention to material conditions before the process, as well as careful settings of molding temperatures and agents. Injection-molded polylactic acid is used for food packaging, fabrics and sanitary products.

Tous les commentaires (3)